7 Best Strategies for Sourcing Engine Parts Globally

In an increasingly globalized economy, sourcing parts engine from around the world has become a vital strategy for manufacturers and suppliers aiming to stay competitive. As industries continue to evolve, finding the right engine components at the best prices while ensuring quality and reliability is paramount. This blog explores the seven best strategies for effectively sourcing engine parts globally, providing a comprehensive guide for businesses looking to optimize their supply chain.

From leveraging international suppliers to utilizing technology for better visibility and communication, these approaches can significantly enhance operational efficiency. Whether you are a seasoned procurement professional or a newcomer to the field, this guide will equip you with the essential tools and insights needed to navigate the complexities of global sourcing for parts engine successfully.

From leveraging international suppliers to utilizing technology for better visibility and communication, these approaches can significantly enhance operational efficiency. Whether you are a seasoned procurement professional or a newcomer to the field, this guide will equip you with the essential tools and insights needed to navigate the complexities of global sourcing for parts engine successfully.

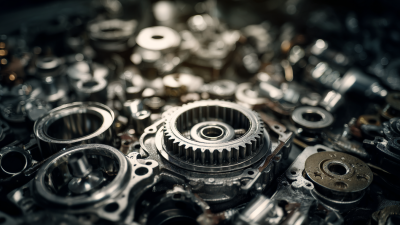

Identifying Reliable Suppliers in the Global Market for Engine Parts

In the competitive landscape of the global engine parts market, identifying reliable suppliers is paramount for manufacturers seeking quality and cost-efficiency. A recent report by ResearchAndMarkets estimates that the global automotive parts market will reach $1.1 trillion by 2025, highlighting an ever-growing demand for high-quality engine components. With this growth comes the challenge of supplier reliability, where businesses must navigate diverse regulatory environments and varying standards of quality.

To effectively identify trustworthy suppliers, manufacturers should prioritize companies with established certifications, such as ISO/TS 16949, which is essential for automotive components. According to a survey by the Automotive Industry Action Group (AIAG), 77% of suppliers with this certification reported improved product quality and reliability.

Furthermore, leveraging digital platforms like Alibaba and ThomasNet can enhance supplier visibility but requires due diligence in assessing supplier reviews and ratings. A substantial 60% of companies have found that using e-commerce platforms enables better supplier relationships and increased access to global markets. By emphasizing these strategies, manufacturers can source engine parts more effectively while minimizing risks associated with supplier reliability.

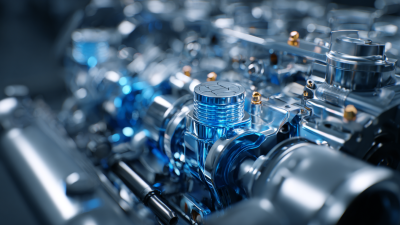

Leveraging Technology for Efficient Sourcing of Engine Components

In the age of globalization, sourcing engine parts efficiently has become essential for manufacturers aiming to optimize their supply chains. Leveraging technology can significantly enhance the sourcing process for engine components. Utilize advanced software tools that can provide real-time inventory tracking and supplier performance metrics, ensuring that businesses can swiftly adapt to changing market demands. This approach not only minimizes downtime but also fosters stronger relationships with reliable suppliers.

To further streamline the sourcing process, companies should consider implementing AI-driven analytics. By analyzing historical data and current trends, businesses can forecast their needs more accurately, helping them to prevent overstocking or stockouts of crucial engine parts. Additionally, establishing a digital marketplace for engine components allows for greater visibility into global suppliers, enabling businesses to compare prices and quality swiftly.

Tip: Always ensure digital platforms have robust security measures in place to protect sensitive information. Regular audits of supplier relationships can also ensure quality standards are continuously met, maintaining the integrity of your manufacturing process. By integrating these technological strategies, manufacturers can achieve a more efficient and cost-effective sourcing process.

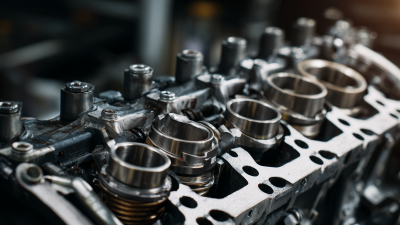

Evaluating Quality Standards and Certifications for Engine Parts

When sourcing engine parts globally, evaluating quality standards and certifications is paramount to ensuring the reliability and performance of your products. Different regions have varying levels of regulatory oversight and quality assurance processes, which means it is essential to familiarize yourself with the certifications recognized in your target market. For instance, ISO certifications can serve as a valuable benchmark, indicating that a manufacturer adheres to international quality management principles. Similarly, automotive-specific standards such as TS16949 play a critical role in assuring that the components meet industry requirements.

In addition to ISO and TS certifications, look for compliance with regional standards such as the SAE International or even local certifications that may indicate a manufacturer’s commitment to quality. Understanding how each certification is applied and enforced in different countries will help you decipher the credibility of potential suppliers. Regular audits and inspections of suppliers can further ensure that they maintain high-quality production standards. By prioritizing suppliers with robust quality certifications, you minimize the risk of sourcing inferior engine parts and enhance the overall integrity of your supply chain.

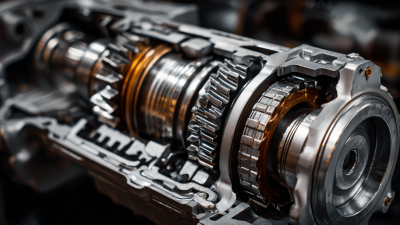

Building Strong Relationships with International Suppliers

Building strong relationships with international suppliers is a critical strategy for sourcing engine parts globally. To foster these connections, it's essential to establish clear communication channels from the outset. Engaging regularly with suppliers not only ensures transparency but also facilitates a better understanding of each party's needs and expectations. Utilizing technology, such as video conferencing and collaborative platforms, can help bridge geographical gaps and maintain open dialogues, which are key to a successful partnership.

Moreover, investing time in visiting suppliers' facilities can significantly enhance relationships. Face-to-face interactions help build trust and allow you to gain firsthand insights into their operations and quality control processes. This approach not only solidifies rapport but also uncovers opportunities for joint problem-solving and innovation. Cultivating long-term relationships with suppliers based on mutual respect and shared goals can lead to improved pricing, access to exclusive products, and priority service during critical times, ultimately benefiting your supply chain and business growth.

Cost-Effective Strategies for Shipping and Logistics in Sourcing

When it comes to sourcing engine parts globally, implementing cost-effective shipping and logistics strategies is crucial for maintaining profitability. According to a report from Deloitte, logistics often accounts for about 10% of the total cost of goods sold in manufacturing industries. Therefore, businesses must focus on optimizing their logistics processes to reduce overheads while ensuring timely deliveries.

One effective strategy is leveraging technology for supply chain visibility. A survey by McKinsey states that companies with high supply chain visibility can reduce logistics costs by up to 15%. By using advanced tracking systems and real-time data analytics, organizations can monitor shipments, manage inventory effectively, and respond to disruptions promptly. Furthermore, consolidating shipments can lead to significant savings; the Global Trade Management Report notes that businesses that consolidate their logistics can save up to 20% on freight costs.

Additionally, forming strategic partnerships with local suppliers can enhance cost efficiency. A report from the Council of Supply Chain Management Professionals highlights that companies utilizing local suppliers can reduce lead times by 50%. By fostering relationships with nearby manufacturers, businesses can not only decrease shipping distances but also benefit from reduced tariffs and faster turnaround times, ultimately resulting in a more agile supply chain.

7 Best Strategies for Sourcing Engine Parts Globally - Cost-Effective Strategies for Shipping and Logistics in Sourcing

| Strategy | Description | Cost Savings (%) | Logistics Time (Days) | Risk Level |

|---|---|---|---|---|

| Bulk Purchasing | Purchase larger quantities to negotiate better pricing. | 15% | 14 | Medium |

| Direct Sourcing | Source parts directly from manufacturers to cut middlemen costs. | 20% | 10 | High |

| Local Sourcing | Find suppliers close to your location to reduce shipping costs and times. | 10% | 2 | Low |

| Negotiation | Engage in price negotiations with suppliers to lower costs. | 5% | 7 | Medium |

| Utilize Technology | Leverage software and tools for efficient sourcing and supply chain management. | 18% | 5 | Low |

| Supplier Diversification | Don't rely on a single supplier; diversify to mitigate risks and costs. | 12% | 12 | Medium |

| Consolidate Shipments | Combine shipments to save on transportation costs. | 8% | 8 | Low |

Related Posts

-

12 Effective Tips for Choosing the Best Engine Parts

-

Engine Parts Comparison Unveiling Reliability and Performance Metrics for Global Buyers

-

Discover Premium Remanufactured Engine Parts from China’s Leading Manufacturing Factory

-

Innovations in Engine Components Shaping the Future of Automotive Technology in 2025

-

Quality Triumphs in Global Markets Unveiling Best Auto Spare Products from China

-

How to Optimize Your Vehicle's Performance with Quality Transmission Auto Parts