Engine Parts Comparison Unveiling Reliability and Performance Metrics for Global Buyers

In the dynamic world of automotive engineering, the reliability and performance of parts engine play a pivotal role in determining the overall efficacy of vehicles. As global buyers seek the best options for their mechanical needs, understanding the diverse range of engine parts available is essential. This blog delves into a detailed comparison of various engine components, highlighting their performance metrics and inherent reliability.

By examining the challenges and common problems associated with different types of engine parts, we aim to equip buyers with the knowledge necessary to make informed choices. Whether you are looking to enhance your vehicle's efficiency or simply seeking to understand the intricacies of engine components, this exploration will unveil critical insights that cater to both novice enthusiasts and seasoned professionals alike. Join us as we navigate through the complexities of parts engine and uncover the best solutions for your automotive requirements.

Importance of Engine Parts Reliability in Global Markets

In today's competitive global markets, the reliability of engine parts has become a crucial factor for manufacturers and consumers alike. As industries strive for higher efficiency and lower operational costs, the performance metrics of engine components are under constant scrutiny. Buyers are not just looking for any engine parts; they seek those that promise longevity and dependability under various operating conditions. These attributes not only enhance the overall performance of the engine but also reduce the frequency of maintenance, leading to significant cost savings over time.

Furthermore, the importance of reliability extends beyond mere functionality. For global buyers, the reputation of suppliers and the consistency of their products play a pivotal role in purchasing decisions. Engine parts that consistently perform well instill confidence, ensuring that businesses can meet their production timelines and maintain customer satisfaction. As manufacturers increasingly prioritize quality assurance and rigorous testing, understanding the comparative reliability of engine parts becomes a key strategy for success in the global arena. Buyers who recognize the significance of these metrics will undoubtedly gain a competitive advantage in their respective markets.

Engine Parts Reliability and Performance Metrics

This chart compares the reliability and performance metrics of various engine parts across different dimensions. The data highlights the importance of reliability in global markets for buyers making informed decisions.

Key Performance Metrics for Evaluating Engine Components

When evaluating engine components, key performance metrics are essential for global buyers aiming to optimize reliability and efficiency. Industry reports indicate that engine efficiency can be significantly impacted by components such as pistons, valves, and fuel injectors. For instance, a study by the Engine Manufacturers Association revealed that high-performance pistons can enhance fuel economy by up to 3%, translating to substantial cost savings over time for consumers and manufacturers alike.

Moreover, the durability of engine parts is another critical metric to consider. According to a report from the Society of Automotive Engineers, components that meet or exceed the industry standard for wear resistance can last 30% longer under typical operating conditions. This durability not only aligns with performance but also reduces downtime and maintenance costs, making it a crucial factor for fleet operators managing multiple vehicles. Buyers should prioritize components validated by rigorous testing to ensure they meet these critical performance benchmarks.

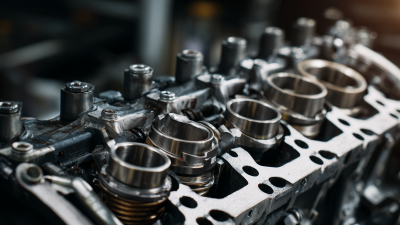

Comparative Analysis of Engine Part Types and Their Benefits

When it comes to purchasing engine parts, understanding the comparative advantages of various types is crucial for buyers around the world. Engine parts can be broadly categorized into OEM (Original Equipment Manufacturer), aftermarket, and remanufactured types. Each category has its unique benefits that cater to different customer needs and preferences. OEM parts are often viewed as the gold standard, as they are manufactured by the same company that produced the original components, ensuring compatibility and adherence to factory specifications. This reliability is essential for performance-driven applications where longevity and efficiency are paramount.

On the other hand, aftermarket parts have gained popularity due to their cost-effectiveness and accessibility. They provide an array of performance enhancements and customizations that can appeal to enthusiasts looking to upgrade or modify their vehicles. However, the quality of aftermarket parts can vary significantly, making it essential for buyers to conduct thorough research before making a purchase. Remanufactured parts offer a middle ground, combining the affordability of aftermarket options with the reliability of OEM parts, as they are restored to meet original specifications. By understanding these distinctions, global buyers can make informed decisions that align with their performance and reliability needs.

Choosing the Right Engine Parts: Factors to Consider for Buyers

When selecting the right engine parts, buyers must consider several critical factors that align with their individual needs and preferences. First and foremost, it's essential to evaluate how these parts will perform in specific vehicle models. For instance, a larger sedan may require different engine specifications compared to a compact hatchback. Buyers should assess the dimensions and requirements of their vehicles to ensure compatibility and optimal performance.

Additionally, budget constraints play a significant role in the decision-making process. High-end brands may offer superior reliability and performance metrics; however, they often come at a premium price. It’s vital for buyers to strike a balance between quality and affordability to secure parts that not only meet their performance expectations but also fit within their financial plan. Considerations such as warranty, brand reputation, and user reviews can guide buyers toward making informed choices that will enhance their vehicle's longevity and functionality.

Engine Parts Comparison Unveiling Reliability and Performance Metrics for Global Buyers

| Part Type | Material | Durability (Hours) | Weight (kg) | Cost (USD) | Performance Rating (1-10) |

|---|---|---|---|---|---|

| Cylinder Head | Aluminum Alloy | 5000 | 8.5 | 750 | 9 |

| Piston | Cast Iron | 6000 | 1.2 | 200 | 8 |

| Crankshaft | Forged Steel | 8000 | 12.5 | 1200 | 10 |

| Oil Pump | Cast Aluminum | 4000 | 2.0 | 150 | 7 |

| Timing Belt | Synthetic Fiber | 3000 | 0.5 | 50 | 6 |

Strategies for Enhancing Engine Performance through Quality Parts

Enhancing engine performance is a critical focus for automakers and buyers worldwide. Recent studies reveal that integrating hydrogen enrichment in diesel blends can improve combustion efficiency and reduce emissions, showcasing advanced combustion strategies. For instance, a study on hydrogen-enriched n-pentanol/diesel blends demonstrated notable improvements in performance metrics, indicating a promising route for achieving both environmental compliance and operational efficiency.

To further enhance engine performance, consider adopting optimized injection strategies. Research has shown that optimizing injection techniques in heavy-duty diesel engines can significantly minimize greenhouse gas emissions while maintaining power output. Using advanced combustion simulations, manufacturers can develop tailored solutions that meet stringent emission standards and elevate engine reliability.

**Tips for Global Buyers:**

1. Look for engines that utilize advanced fuel and air management technologies to maximize efficiency.

2. Consider suppliers who implement AI and machine learning techniques in their production processes, as these can lead to superior parts that enhance overall engine reliability.

3. Pay attention to certifications and performance reports that indicate how engines perform under various operational conditions, especially at high altitudes.

Related Posts

-

Innovations in Engine Components Shaping the Future of Automotive Technology in 2025

-

12 Effective Tips for Choosing the Best Engine Parts

-

Discover Premium Remanufactured Engine Parts from China’s Leading Manufacturing Factory

-

Quality Triumphs in Global Markets Unveiling Best Auto Spare Products from China

-

Top 7 Import and Export Certifications for the Best Engine Coolants You Need to Know

-

China's Premier Factory Delivering Unmatched Automotive Spares Worldwide