Innovations in Engine Components Shaping the Future of Automotive Technology in 2025

As we approach 2025, the automotive industry is on the brink of a transformative era, fueled by cutting-edge innovations in parts engine technology. According to a report by Markets and Markets, the global automotive parts market is projected to reach $2 trillion by 2025, reflecting a compound annual growth rate (CAGR) of 5.2%. This surge is driven by advancements in materials science, additive manufacturing (3D printing), and the integration of AI and IoT technologies in engine components.

Notably, lighter and more efficient engine parts are not only enhancing vehicle performance but are also key to meeting stringent emissions regulations. With these innovations, manufacturers can improve fuel efficiency and reduce overall production costs, paving the way for more sustainable vehicle designs. As we delve into the latest trends and technologies shaping the future of automotive technology, it becomes clear that the evolution of parts engine is at the forefront of this dynamic industry shift.

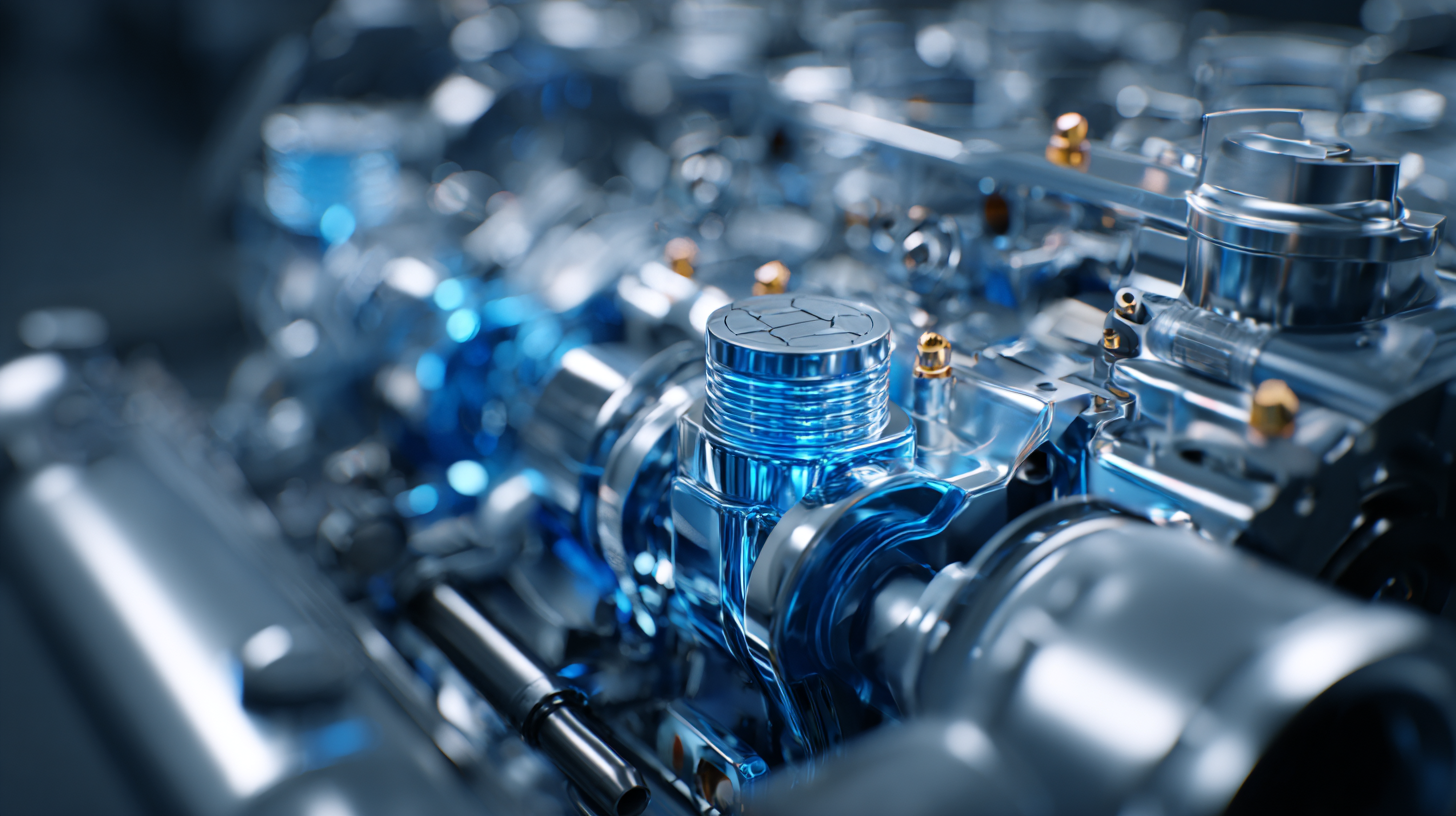

Revolutionizing Engine Efficiency: The Role of Advanced Materials in 2025

As we look towards 2025, the automotive industry is on the brink of a revolutionary transformation, primarily driven by advanced materials that enhance engine efficiency. These innovative components are set to redefine performance metrics, making engines lighter yet more powerful.

Materials like carbon fiber composites and advanced alloys are emerging as game-changers, enabling manufacturers to design engines that not only consume less fuel but also produce fewer emissions. This shift not only meets the increasing regulatory demands but also caters to the growing consumer desire for sustainable vehicles.

Tips for incorporating advanced materials in engine design include leveraging simulations to test the performance of new composites before physical production. Additionally, collaborating with material scientists can lead to breakthroughs that further enhance engine performance and longevity. It's essential to stay updated on the latest research, as the field of advanced materials continues to evolve rapidly, opening new avenues for innovation.

Investing in R&D for these materials is crucial, but so is training your teams to understand and implement these changes effectively. Engineers and designers should be encouraged to think outside the box and explore unconventional uses of materials, potentially leading to unexpected efficiency gains. By focusing on these areas, companies can position themselves at the forefront of automotive technology and create vehicles that truly represent the future of driving.

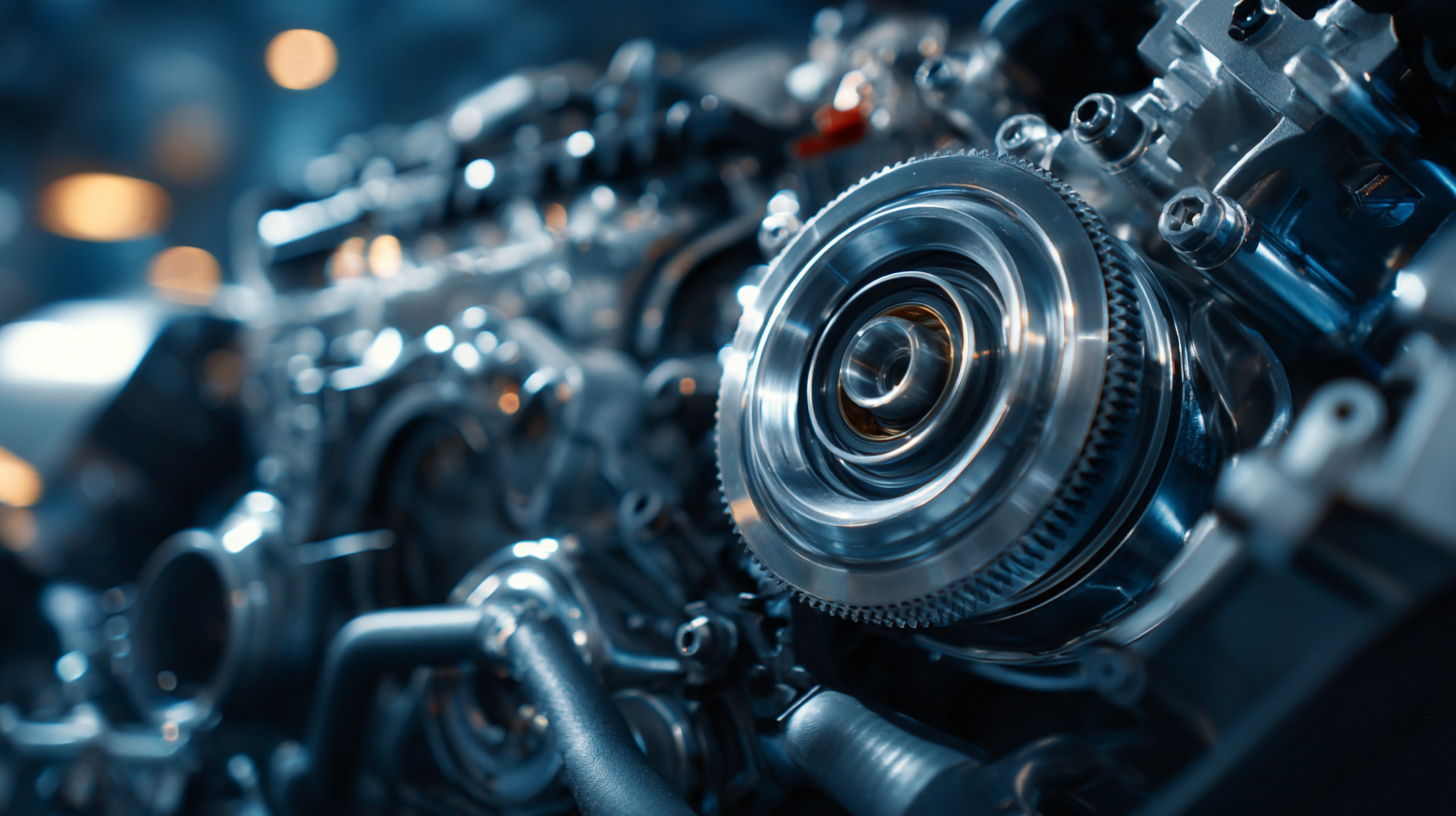

Next-Gen Engine Components: Embracing Modular Design for Customization

The evolution of automotive technology is heavily influenced by next-generation engine components that prioritize modular design, allowing for greater customization. As we approach 2025, the traditional rigid engine architectures are giving way to innovative modular systems that can be easily adapted to meet diverse consumer needs. This shift not only promotes enhanced performance but also provides manufacturers with the flexibility to respond quickly to market demands, leading to a more personalized driving experience.

Modular engine components enable automakers to streamline production while customizing features for specific models. For instance, modular turbochargers or interchangeable cylinder heads can be configured based on the desired power output or efficiency requirements. This approach fosters an environment where innovations can be rapidly developed and integrated, smoothing the pathway for advancements in hybrid and electric vehicle technologies. As manufacturers embrace this modular philosophy, we are likely to see significant improvements in fuel efficiency, reduced emissions, and an overall enhancement in vehicle performance standards.

Modular engine components enable automakers to streamline production while customizing features for specific models. For instance, modular turbochargers or interchangeable cylinder heads can be configured based on the desired power output or efficiency requirements. This approach fosters an environment where innovations can be rapidly developed and integrated, smoothing the pathway for advancements in hybrid and electric vehicle technologies. As manufacturers embrace this modular philosophy, we are likely to see significant improvements in fuel efficiency, reduced emissions, and an overall enhancement in vehicle performance standards.

The Impact of AI on Engine Component Manufacturing and Performance

The automotive industry is on the cusp of a revolution, with artificial intelligence (AI) significantly influencing engine component manufacturing and performance. By 2025, we expect AI-driven innovations to streamline production processes, enhance precision, and reduce waste, leading to smarter and more efficient vehicles. Advanced AI chips, capable of processing vast amounts of data, will enable manufacturers to optimize their designs and operations, resulting in higher performance and reduced emissions.

Tips: Embracing AI technologies not only aids in improving production efficiency but also enhances the overall vehicle performance. Companies should focus on integrating AI systems that can analyze data in real time for better decision-making in manufacturing processes.

Tips: Engaging with cutting-edge AI solutions can provide a competitive edge in the fast-evolving automotive market. It's crucial for teams to stay updated on the latest AI tools and techniques that can transform traditional manufacturing into a data-driven, high-performance operation.

Sustainability in Engine Development: Innovations for Eco-Friendly Driving

The automotive industry is rapidly shifting towards sustainability, with innovative engine components leading the charge for eco-friendly driving practices. According to a recent report by the International Energy Agency, electric and hybrid vehicles are projected to make up 30% of global vehicle sales by 2030. This surge is being supported by advancements in engine technology that emphasize efficiency and reduced emissions, such as lightweight materials and enhanced combustion processes designed to optimize fuel consumption.

One remarkable innovation is the development of hydrogen fuel cells, which present a promising alternative to conventional gasoline engines. A study from McKinsey & Company projects that the global hydrogen fuel cell vehicle market could reach $900 billion by 2030, driven by the need to meet stringent environmental regulations and consumer demand for cleaner alternatives. Furthermore, incorporating renewable energy sources into the manufacturing processes of engine components not only minimizes carbon footprints but also enhances the sustainability quotient of vehicles, making them appealing to environmentally conscious consumers. As the industry evolves, these innovations signify a pivotal movement towards a greener future in automotive technology.

Innovations in Engine Components Shaping the Future of Automotive Technology in 2025

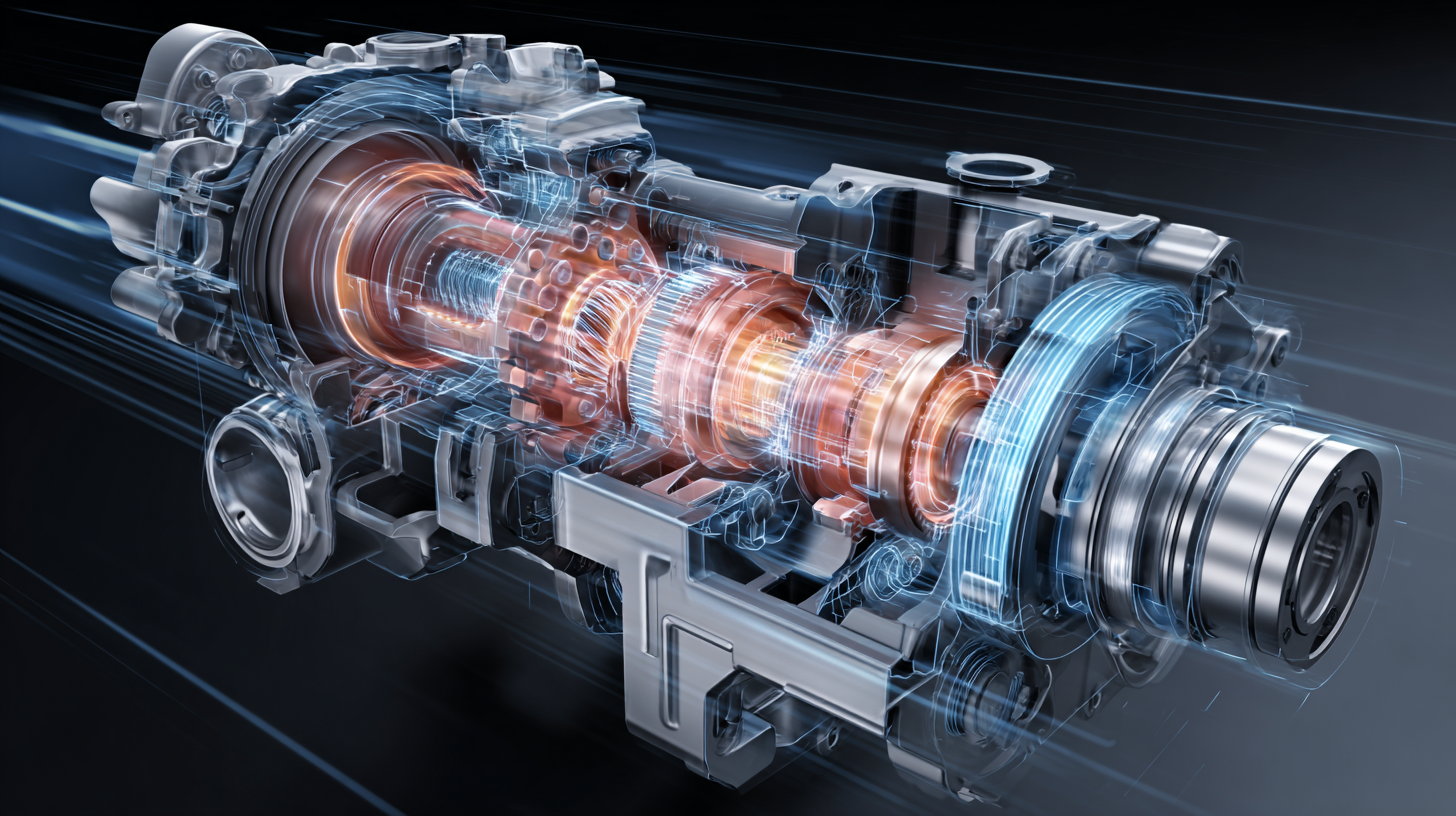

Driving Towards Electrification: Engine Components in Hybrid and EV Technology

The automotive industry is rapidly evolving towards electrification, with innovative engine components playing a crucial role in this transformation. As manufacturers strive to meet consumer expectations for greener transportation solutions, the focus on hybrid and electric vehicle (EV) technology has intensified. The integration of advanced components such as the eAxle is leading the charge by combining essential elements for vehicle propulsion in a compact design, enhancing efficiency and performance. These advancements are addressing environmental concerns while providing exciting options for drivers.

Moreover, wide bandgap (WBG) technology is revolutionizing power electronics in electric-drive vehicles, significantly reducing component size and increasing overall efficiency. This shift not only improves vehicle performance but also ensures that affordable, class-leading models remain accessible to a broader audience. As the energy transition picks up momentum, the development of innovative driveline lubricants and thermal management strategies will further drive the growth of hybrid and EV sectors, marking a significant leap towards a sustainable automotive future.